NYE was a fun one - the weather at the cabin was beautiful. A blue bird day with fresh snow and powder on the ground, a gentle little breeze the whole day and any effect from the foot or two of water that had been flowing under the cabin from the massive flooding a few weeks prior was gone.

The cabin on NYE - couldnt have asked for better weather!

The cabin on NYE - couldnt have asked for better weather!

I'd gotten everything charged, and found a nice tough box for the receivers to go in. I only needed 6 for my show, but brought a spare just in case. Again, this case is maybe 200 dollars in receivers, which is insane given that this is 7 zones, each of which could support 128+ cues a piece. I'd gotten everything charged up at home beforehand.

Setting up the show was a breeze - the program's loadout export function gave me a good 'pick sheet' to figure out what I needed to get out from storage, and the rack fusing grid made getting those set up so dang easy - really happy with that function:

Some photos from the setup that comes from the BYH program:

Loadout sheet, cue assignment and the rack grid that is automatically generated from the BYH UI - this was super helpful when I was packing/fusing the rack, and in the field when I was connecting the cues

Loadout sheet, cue assignment and the rack grid that is automatically generated from the BYH UI - this was super helpful when I was packing/fusing the rack, and in the field when I was connecting the cues

The 4x14 and 2 5x8 racks all set up according to the loadout sheet that was generated by the program with their ignitor leads labeled with the cue # they should be plugged into

The 4x14 and 2 5x8 racks all set up according to the loadout sheet that was generated by the program with their ignitor leads labeled with the cue # they should be plugged into

So once the excavator got started, which took some convincing given in the span of a couple weeks it was up to the floor with floodwaters, then subjected to consistent 20 degree nights, I'd plowed out the 5 stations where racks and cake sheets would go and figured I'd get things wired up right before the show that I'd told folks started at 9pm (old person NYE on the W coast) on the dot.

All the stations, pre-getting-cakes-secured

All the stations, pre-getting-cakes-secured

There was a lot more I could have done at home - wired ignitors into the cakes and numbered the leads being the most obvious in the cold... But nevertheless had plenty of time up until maybe 8:15pm when I went out to connect the ignitors to the cues. One thing I realized here is that my push connectors suck in the cold. The push surface is so small that gloves are out of the question, and they took a lot of pressure to open up... after 140 different connections, my thumb was wrecked... Regardless, everything was hooked up and it was time to turn them on and get the show loaded and going. Thats when things started to get fun....

Failure

Every bit of "testing" I'd done was always with the receivers on, plugging cues in and seeing the status light change and the continuity show on the app's screen. In retrospect, at no point did I ever hook up cues to a turned off receiver and then try to turn it on. Well, that was a problem as I'd come to find out. In short, I'd breezed by the 'pulldown' circuit for the output enable for the shift register that controls the firing MOSFETs. Without this pulldown circuit being effective, the board can start leaving this output enable in a floating state. Think of a flag flapping in the wind, where side to side is off/on. Startup is a noisy process for the signals going to the registers, so generally speaking there will be random outputs that are turned on. The only defense against this is holding the output enable pin HIGH to disable the outputs.

If this isn't working properly, and there are 16+ cues plugged in to a receiver, it is possible for it to start and attempt to fire every cue. The good news is that it at startup, before any caps can charge, the system cannot supply the power to fire that many cues at exactly the same moment. What I observed is that the receiver didnt want to turn on. At first I thought it must be the cold, but yanking the cue module off, It started up fine. The mistake was when I plugged it back in, pulling a few cues and firing it back up. On doing that, there was the inevitable snap of an ignitor going and sure enough, 3-4 fuse lines were going on my center rack.

For whatever reason, maybe just that I figure all was lost and the show had 'started' resorted to the exact thing I built this entire system to avoid - sprinting manically with a blowtorch. Long story short, I got through it, but with the left and right stations being almost 50yd apart, I packed whatever cardio I fell short on in 2025 with about 3 hours to spare in the year. Ripping out the ignitor, and just gunning the side with the torch, I was barely keeping track of what was fired, and apart from a moment looking up to appreciate the "sky on fire" look of a NOAB nishiki willow finale, never really got to enjoy it.

What was left when the dust settled was a handful of cakes fully involved in fire from being frantically torch-lit, the heavy hanging smoke that can only come from 10 minutes of sky vomit, and about 25% of the hearing i started the day with. Felt deeply in me was just the disappointment of such clear failure. Of course it was still fun, and I was able to shrug a lot off in the moment just in the ritual of piling all the fired cakes and plywood onto a giant pallet bonfire. As i sat more in the night, it really started to sink in. The reality of it was that the second those shells fired, I was in go-mode and no amount of intervention could have made me stop and think critically for a second to unplug everything, start the receivers, then plug everything in as I'd done with all my testing. If that had been the case, aside from maybe 20 misfired shells (of about 140), I'd have been able to start, run and enjoy the show.. albeit maybe 10-15 late. If it was just me and I didnt have 20-30 strangers flanking the property watching, I'd have taken that time and done it right... But feeling such a punctual duty, that went right out the window.

The worst part of it is that in my wonderful state, we have 3 days a year that we can discharge fireworks, and 4th of July at the cabin usually means some degree of restricting what I'm using to avoid causing a wildfire (in the rare case there isnt already a burn ban). A NYE with this perfect of weather is such a rare thing... In past years, it was either active snow, rain, or hanging fog... To have wasted that was the worst part.

Revision

Obviously I needed to (and have) fix the issue with the floating input to the ignition shift registers... But my head was stuck on the cue modules and overall how to make both at-home and on-site prep more straightforward for shows.

The Cue module

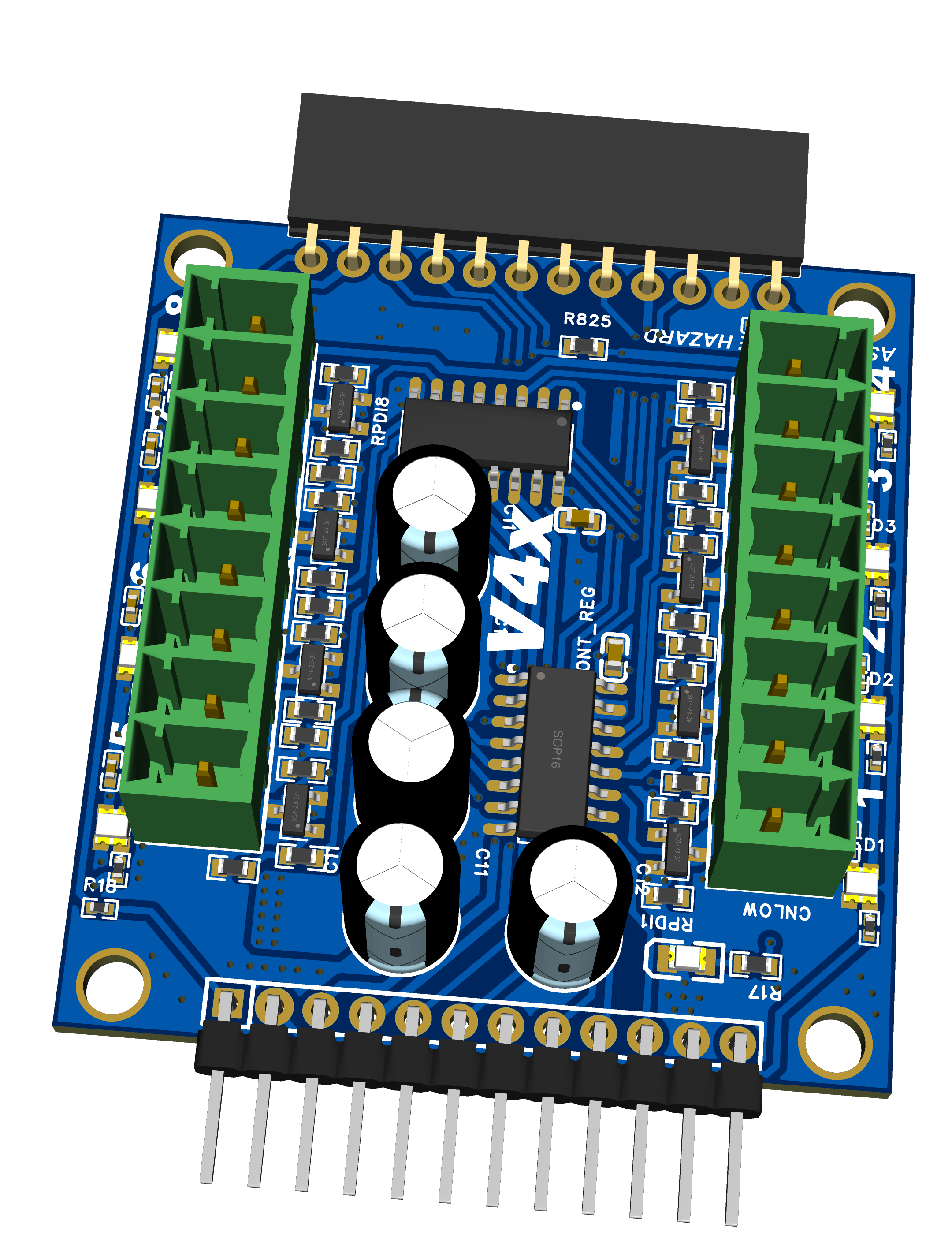

The cue module got a pretty extensive reboot here. Still backwards compatible, but that's about it.

The biggest change here is going to a plug-based system. The individual press-fit pair connectors were replaced by 2 8-pin connectors. The cool part about this is that one could have labeled connectors that are either screw or spring push fit that I can put on the ignitors at home.. Then all I need to do in the field is plug it in. Racks could use male 8 pin connectors, where cakes could be their own 2 pin ones.

Using this connector allowed me to compact and re-route the board to take off about 15mm of length, making it a bit more compact.

With the new routing, I was able to pack a few more EL caps into there to smooth out some firing spikes.

The Receiver

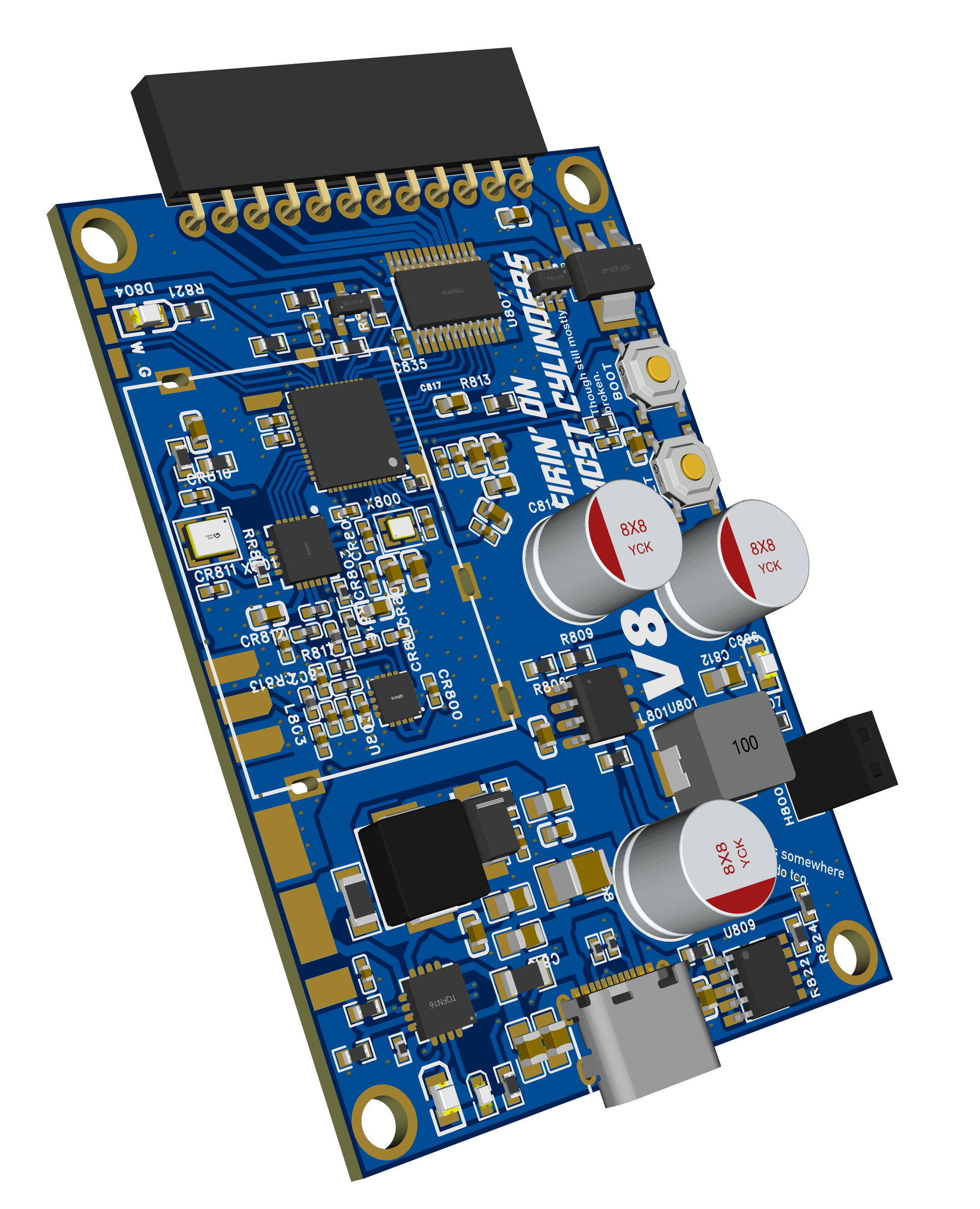

Well now we're at V8. This is the same 4 layer, controlled impedance board with onboard RF. The obvious first fix was the pullup circuit for the firing shift register. One other significant change here was adding a USB-PD circuit on the USB plug to ideally be able use off-the-shelf USB chargers. What I'd been using was a homemade 12v supply that powers through a male USB-C plug. with the PD chip, one wouldnt need any kind of special charger.

The Cost

I'd put off any hardware development due to tarriffs... but I couldnt wait on this one, I didnt panelize at all, which sort of hurt the $/board... but end of the day I was looking at 500 bucks for 15 receivers and 30 cue boards.... Yay.