The previous post Had highlighted hardware failures/inconveniences during the NYE 2025 show, and the end of that was some amount of optimism about the newest round of hardware revisions - The v0.8 receiever and v0.4 cue.

Well. That didn't go great.

To be fair, I would hardly call them systemic failures, just happy little life lessons in the form of multiple-hundred-dollars of unusable custom hardware.

Why the V0.8 Receivers were terrible.

So in a way, it wasn't really a revision unique to the v0.8 receiver, it was more a realization of a larger issue with the receiver in general. The NDP2450KC buck converter controller I was using had been on the boards since about v0.4. Why I thought a 5A continuous output supply was enough is beyond me, but more importantly, it was a fairly feature-limited IC, albeit the thing was damn efficient.

The v0.4 cues had positions for 4 bulk capacitors each. So excitedly hooking 4 of these up to a single receiver revealed an unfortunate thing. It wouldnt turn on. With over 6500uf of capacitor on the 5v line, the inrush current from trying to fill those up had the converter just saying "nawwww". Lacking any kind of soft-start feature that I could access, there was just no way to get around it. Those capacitors are important as they smooth out a lot of the nastyness that can come from a lot of cue firing. If we're chaining 6+ cues off a single receiver, that last queue is a wayyys away and is still needing a solid 5v for its shift registers.

What was great about the V0.8 Receivers

One other thing that was added to the V0.8 recievers was a USB-PD chip that allows it to negotiate over it's USB connection with a charger to provide the needed 12v for charging. A much earlier board revision, in a fit of dumb, actually had a boost circuit on the 5v of the USB to feed the TP5100 charger.... But at some point I removed it and opted just to make USB-C plugs connected to 12v power bricks and use those to charge. But for one, I had to keep these chargers around that could kill folks only-5v-tolerant USB devices, and 2, if I ever wanted folks to use these, they had to use native USB charging.

So to my delight, this worked wonderfully on V0.8!

Also fixed was the logic around the master enable for the output shift registers (what fires the actual ignitor), so it could no longer, in certain rare cases, fire everything on boot. So that's nice.

The v0.4 cues were unusable

Well, turns out I need to actually check EasyEDA's footprints still. I got burned by this a bit ago on an 0603 LED, where the footprints in EasyEDA were inverse of the actual LED, so when placed on the assembled board by JLCPCB, they were all backwards. Easy enough here to resolder, but in the case of the 4-pin WS1218b who's VCC and GND pin were switched in the footprint, I was simply cooked and now had 30 unusable boards. Cool. So I fixed that.

The glorious v0.9

It's funny because I'm already thinking of a post in some amount of time that talks so much trash about how terrible the v0.9 boards are. But right now, it's optimism and wonder, which frankly is a state i want to be in as long as humanly possible these days. So lets talk about what was done on this new, exciting revision:

140% more power

The v0.9 now uses a 12A continuous buck circuit.

It is based on the TI TPS56C230RJER and while slightly less efficient, is a beast. Given I'm slightly more informed than I was when I put together the last 5v supply circuit a year ago, I utilized some better practices/design strategies to cut down on noise. So that's nice too. Testing the output at rest, the thing is a rock-solid flat line.

Pretty lights

The single status light on all prior receivers really was being used to it's full extent. It's flashing signaled how well receivers were synced (together == synced) and the rate in which it was blinking, if one was perceptive, could visually convey what state it was in. But obviously that sucks - It is much better to be be able to look at a receiver and know the important things about it. I could sort of hack this leveraging the addressable LEDs on the cue module, but this was pretty hacky.

So I took the opportunity here to place 3 of the same addressable LEDs on the receiver itself. These each can be any brightness/color, same as the cue's LEDs. So v0.9 boards use these heavily to convey status. On boot, they do a pretty cycle, in the middle of which is a gradient lighting display that shows the battery %. The blinking is done in kind of a "fade out" way that looks super cool (fast on then slow fade out over 1-1.5sec).

When running, the first LED is used to convey transmission status, blinking white when receiving a message from the dongle that it responded successfully to. Red if it had received, but failed return transmit.

The second LED is the sync led, which flashes at a particular interval relative to its clock. Other receivers, if on the same synchronized clock will flash at the exact same time. The color of the flash corresponds to battery % -- 0 == red, with a gradient all the way to 100% = green. So one can easily tell battery status by just looking at the receiver. This is all redundant to what one sees on the receiver info on the laptop, but oh well. The third light indicates the state of the receiver. Off means no show loaded, just sitting. Then there are colors for certain states, like show load start, show load complete, start wait, start countdown, and running a show. I can't express how useful that is for debugging. In addition, I refactored the upper case a bit, opting to use a white plastic and create a "cage" around each light and thinly printing the area at the top of those boxes. What results is a really cool flush surface where these squares light up from the LEDs below.. The added convenience too of not needing to cut and place clear plastic tubes to transfer the light to the outside of the case!

Split Power planes

Back to dumb PCB stuff - Since I'd gone 4 layer, that inner power layer was just all 3v. For one, this didnt seem great for the RF stuff, as that 3v3 was also under things like the inductor the 5v buck, and generally just a lot of places it didnt need to be. Also, routing seemed to suck just getting the more important 5v to where it needed to go.

So I took it upon myself to divide the inner power layer up into the appropriate voltage for the area:

This made routing a lot easier, and also seemed to really improve how clean the RF bits are.

Where we're at

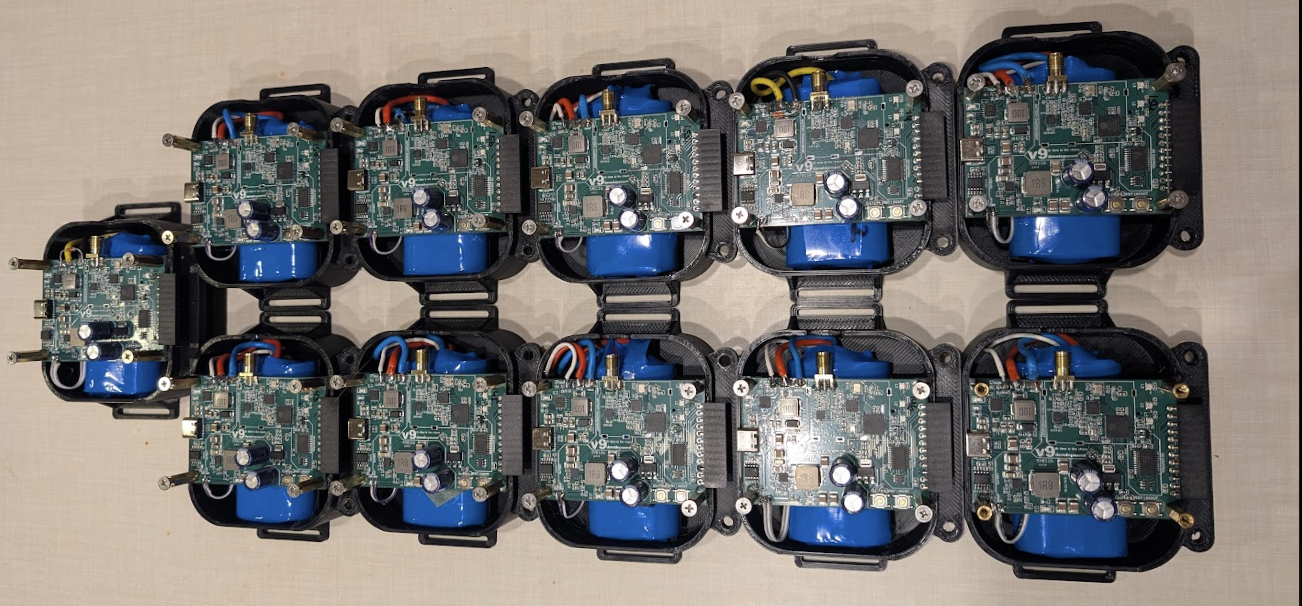

I now have 30 of the receivers, and 30 of the new cues to play with!

So getting existing receivers upgraded is the name of the game, and maybe even adding more. Pressure testing thus far has gone really well, to the degree that I've already sent hardware to folks to test out themselves!